IONEX®

TYPE OP

CATALYST

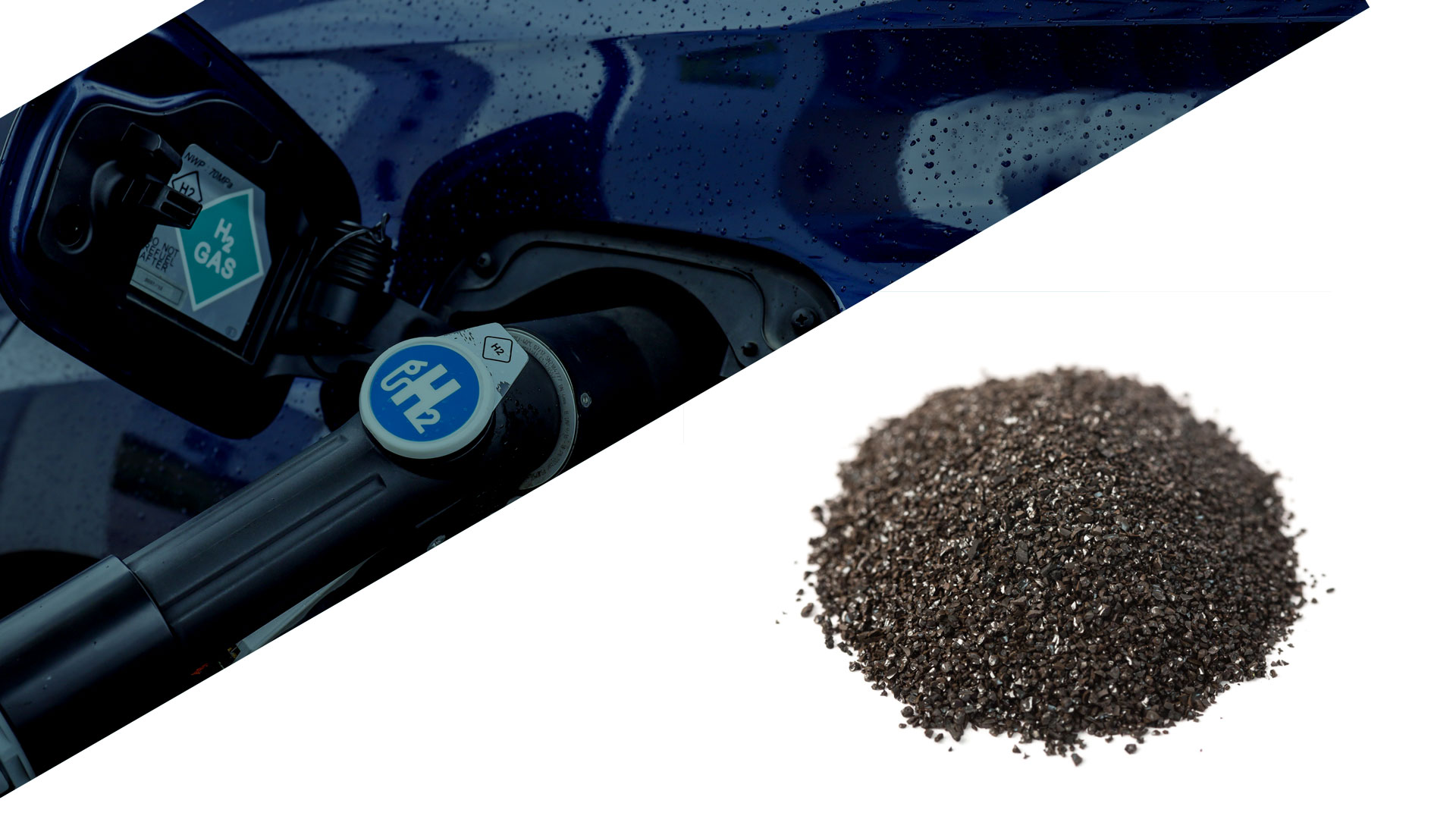

Ionex® Type OP Catalyst rapidly converts ortho to para hydrogen during the liquefaction process to minimize liquid hydrogen (LH2) boil-off during storage.

That’s why market leading energy companies, hydrogen liquefaction equipment manufacturers and technology licensors rely on Ionex® Type OP Catalyst to protect LH2 yields and maximize revenue.

HOW IT WORKS

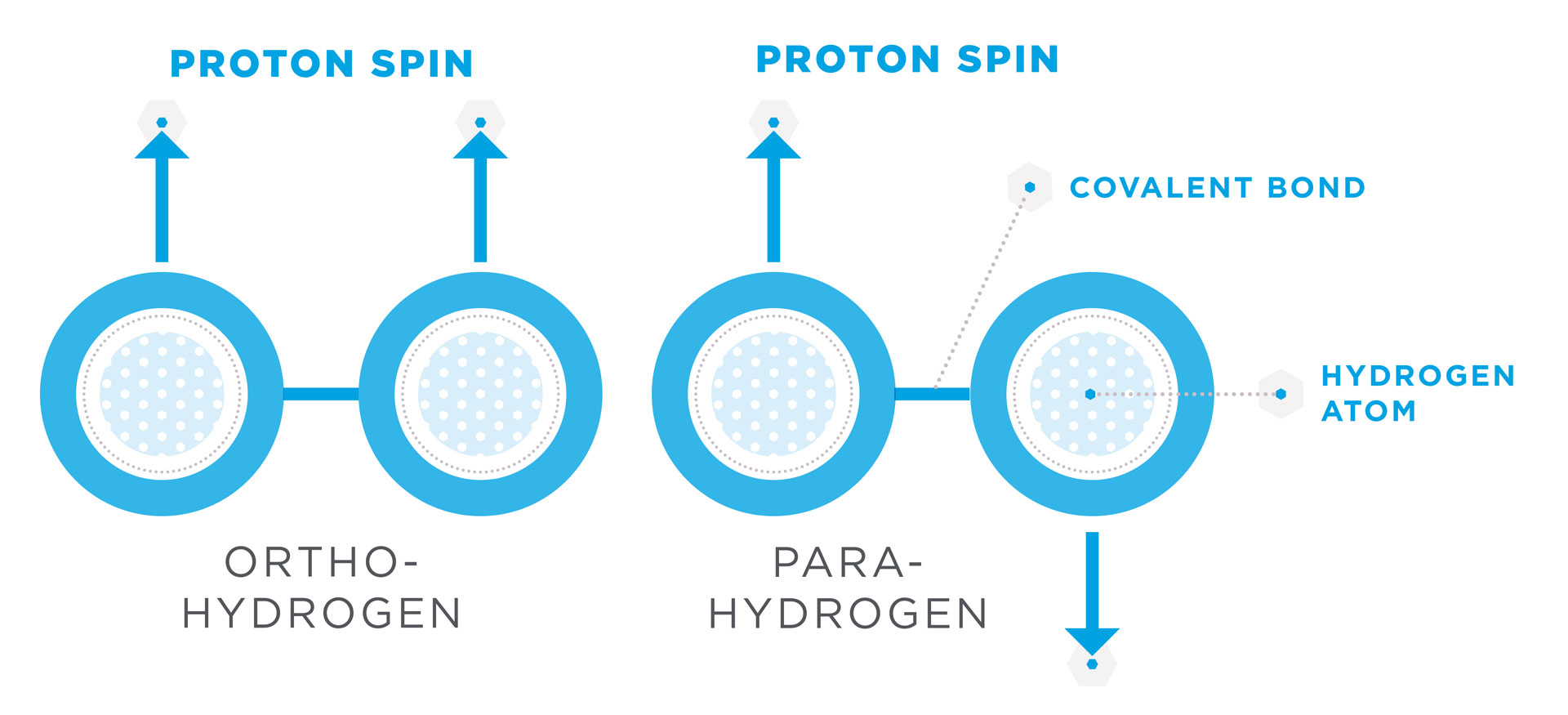

Ionex® Type OP Catalyst accelerates the spin isomer change from ortho to para hydrogen during liquefaction.

Fast catalysis during liquefaction ensures that only stable para hydrogen is present for cryogenic storage. This results in less than 1% percent hydrogen loss per day in a well-insulated Dewar, compared to 18% per day without Ionex® Type OP Catalyst.

THE BENEFITS

Maximizes yields

Specifying Ionex® Type OP Catalyst into hydrogen liquefaction processes limits boil-off loses

Outstanding value

Ionex® Type OP Catalyst is significantly more efficient than supported chromium oxide catalysts

Proven performance

Highly efficient liquefaction catalyst with exceptional performance that is backed with in-service data

WHERE IT’S USED

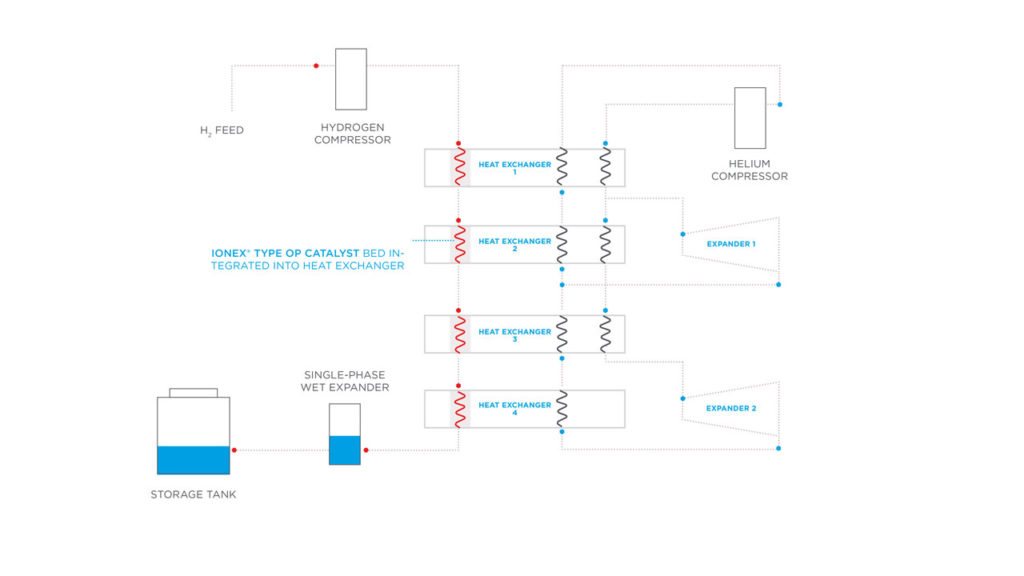

Ionex® Type OP Catalyst is filled inside the heat exchanger to accelerate the catalytic conversion of ortho to para hydrogen. The design of the ortho to para hydrogen heat exchanger and reactor vessel has significant impact on the efficiency and cost of the hydrogen liquefaction process.

TECHNICAL SPECIFICATIONS

Ionex® Type OP Catalyst efficiently catalyses the conversion of ortho hydrogen to para hydrogen. Due to its large surface area and particle size uniformity, rapid conversion and uniform flow characteristics are assured.

WHAT WE KNOW ABOUT LIQUID HYDROGEN

- When hydrogen is liquefied at low temperature, there is a slow spontaneous transition to about 90% para, with heat energy released as the molecules convert to the lower energy state.

- As a result of this change, a thermally isolated tank of liquid hydrogen prepared without conversion to the para form will lose about 18% of its volume during the first day of storage and up to 50% in the first 10 days.

- In the absence of this internal evolution of heat, the heat transfer to a well-insulated Dewar may result in a loss of less than 1% per day.